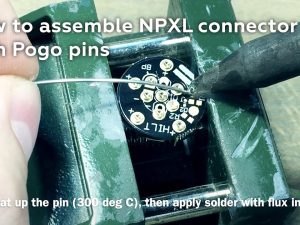

If you are considering making connector prototypes or manufacturing your own DIY test fixtures, jigs, end-effectors, or connectors then test probe drilling with a drill machine with a high speed spindle and reasonable accuracy will be needed for drilling the probe plate, support plates, or connector housings.

Some components to consider would be a driller/router with variable speed, a bench-top pillar drill with a proper work holder for the drill, and/or a 3-4 axis CNC driller router with an X Y it will likely be suitable so long as it is in reasonably good condition. Lack of precision can be a problem with larger machines, cheaper models, or with older, worn machines. But if you already have a machine it is certainly worth trying it out. Our fixture kits include a small piece of probe plate material to practice drilling on, so you can test without damaging your kit.

If you are going to buy something your choices are essentially a high-speed rotary tool (such as a Dremel tool), a small bench-top pillar drill, or a small bench-top mill.

High-Speed Rotary Tool

The cheapest option is undoubtedly a high-speed rotary tool. You will also need a matching drill press accessory. This is essential – you will not be able to drill straight and true without it. Most tool manufacturers have such an accessory to suit their popular tools. The combination should cost around a hundred dollars.

We have had success with the Dremel model 395 tool and Dremel model 212 drill press stand. This is about the cheapest combination capable of producing good results. That stand is not great but it is adequate if used with care. At about the same price Dremel also offers the 220-01 Rotary Tool Work Station which is a newer product with more flexibility.

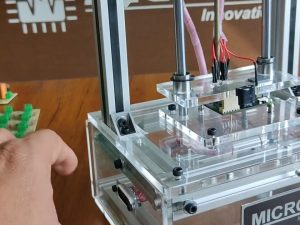

If you plan to do more than prototyping or very small quantities of fixtures or connectors, we’d recommend stepping up to a low to mid-level of CNC automation. These combine positioning capability along with a reasonable spindle speed for drilling G-10 and other plastics commonly used in creating pogo pin jigs and test fixtures. A decent system can be purchased for a lot less than a commercial system that would still require upgrades for commercial production. We’ve done some research for you and the system below is a good candidate:

No products found.

An alternative that gets some good reviews is the MICROMOT system from German company Proxxon. The combination of Proxxon IB/E Professional Rotary Tool and Proxxon MICROMOT Drill Stand MB 140/S is closer to two hundred dollars but appears well made.

Proxxon 28600 Micromot Drill Stand MB 200 , Green – Amazon.com

Regardless of your approach with some basic fabrication skills and some practice, you’ll be drilling and filling test fixtures or spring loaded connectors in no time!