We wanted to see how much gold one kilogram of these pins contains so we investigated using a gold recovery process!

Pogo pins are typically used as connectors or test pins and are made from a mix of common base metals and precious metal plating. Once the product with pogo pins reaches end of life, or when test probes have been used and replaced, they typically end up in a scrap recovery program of some sort. Many test probe manufacturers will accept the return of used test probes and some even offer payment based on current market rates.

A pogo pin gold contact recovery process to extract gold from scrap parts typically involves the following steps:

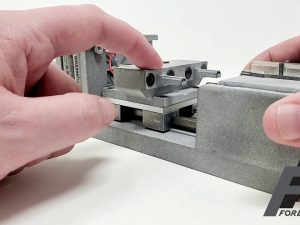

- Collecting gold-containing metal scraps such as spring contacts (pogo pins), spring loaded connectors, test probes, receptacles, etc.

- Stripping and cleaning the spring contacts to remove gold from the scraps.

- Methods include:

- Chemical methods methods such as the mercury method and the Borax method.

- Non-toxic solution of acetic acid and an oxidant to dissolve gold from circuits. This process can be performed in about 10 seconds, leaving intact other metals in printed circuit boards.

- Recycle using a more complex process. Gold extraction from use spring contacts and probes typically requires specialized knowledge and equipment, involving steps like disassembly, chemical treatment, and refining to separate gold from other materials. Cupellation is one advanced process that can be implemented with the alloyed metals which are treated under very high temperatures and then subjected to controlled operations to separate noble metals such as gold and silver.

Additionally, methods for recovering free and coarse gold include direct amalgamation and gravity concentration.